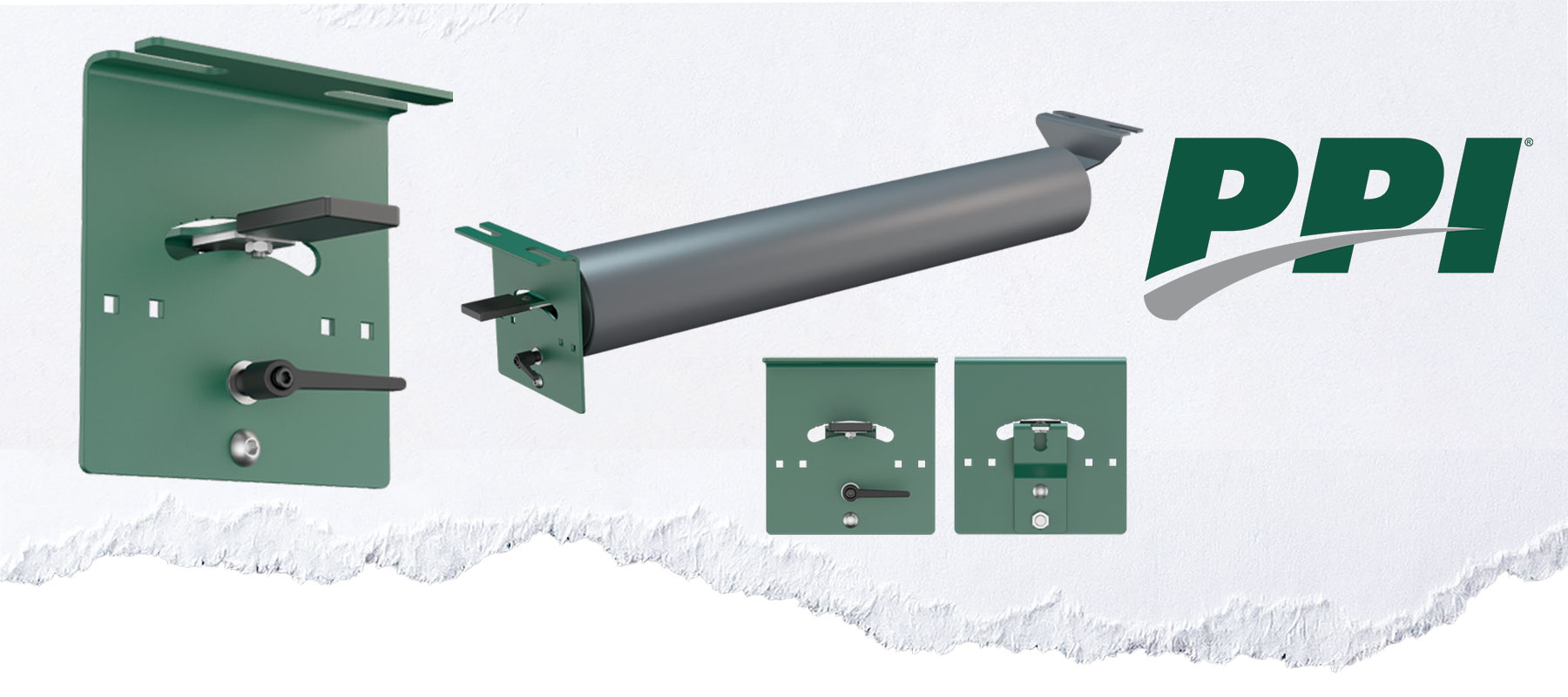

PPI RETURN ROLLER BRACKET

Belt tracking is a major problem in our industry.

It is common that primary pulley such as tail pulleys are moved to track belts, and this is not correct.

All primary pulleys must be kept square to the frame, and the return rollers need to be moved to track the belt.

Moving the primary pulleys puts unequal tension on the belt and may work temporally but with eventually stretch out one side of the belt and cause the belt to be longer on one side than the other causing all kinds of tracking issues.

It also puts stress on the bearings and creates uneven wear on the pulleys

FEATURES AND BENEFITS

- Easily knock/skew return idlers

- Effective method of training belts

- Large range of adjustment

- Easily identifiable brackets, allows users to manage adjustment points

- Maintenance friendly design

- Direct interchange with PPI 4-1/2” drop brackets

- Available for CEMA B, C, & D applications

- FEATURES AND BENEFITS

See attached info sheets and links for more information.

Click to watch the product video

These items are also currently in stock.

PULLEYS

- Pro Duty Drum Pulley

- Heavy Duty Drum (HDD) Pulley

- Mine Duty Drum (MDD) Pulley

- Spiral Drum Pulley

- Heavy Duty Wing (HDW) Pulley

- Mine Duty Wing (MDW) Pulley

- Spiral Wing Pulley

- Quarry Max Duty Wing Pulley

- Grain Herringbone Wing Pulley

- Boot Herringbone Wing Pulley

IDLERS

- Troughing Idlers (TE)

- Impact Troughing Idlers (TEI)

- Self-Aligning Troughing Idlers (TESA)

- Unequal Troughing Idlers (TU)

- Unequal Impact Troughing Idlers (TUI)

- Transition Equal Trougher Idlers (TET)

- Return Idlers (R)

- Rubber Disc Return Idlers (RRD)